-

-

Nozzles

I. Description

II. Types

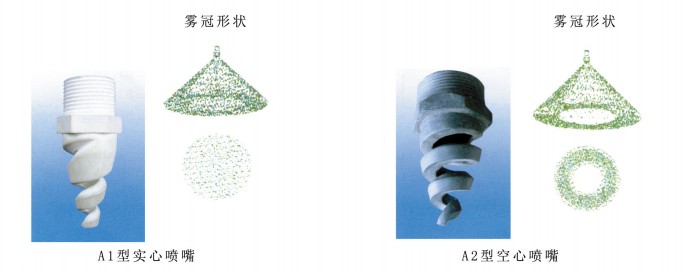

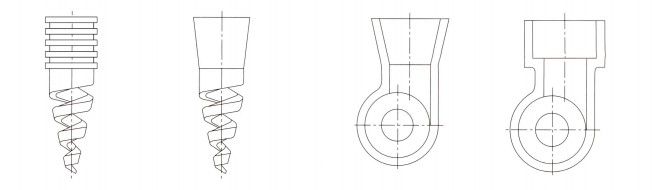

I. A screw-type nozzle

A screw-type nozzle can be divided into A1 solid nozzle and A2 hollow nozzle according to fog crown.

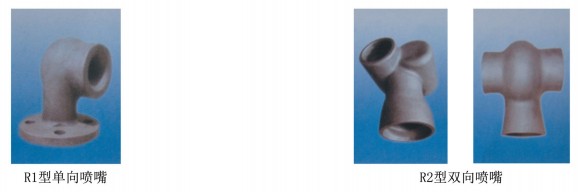

II. R hollow linear nozzle

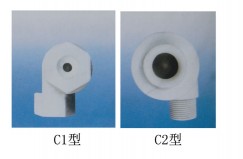

III. C tobacco pipe type nozzle

C tobacco pipe type nozzle can be divided into C1 and C2 two types.

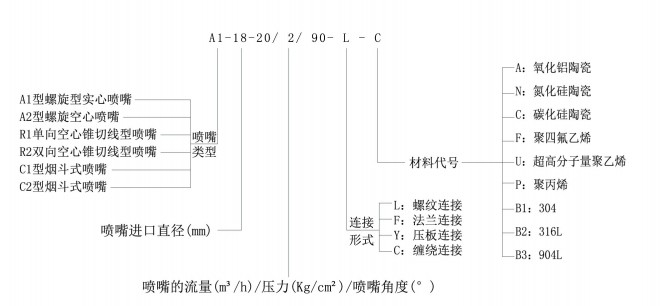

III. Demonstration of model

IV. Materials

Nozzles materials: 1. silicon carbide SiC (code C) 2. Silicon nitride Si3N4 (code N) 3. Aluminium oxide Al2O3 (code A) 4. Ultra-high molecular weight polyethylene UHPE (code U) 5. Polytetrafluoroethylene F4 (code F) 6. Polypropylene PP (code P) 7. 304 (code B1) 8.316L (code B2) 9.904L (code B3)

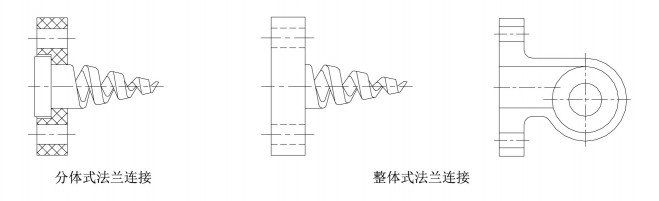

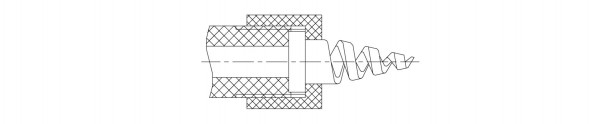

V. Type of connection

Four types: screw type (code L), flange type (code F), pressing plate type (code Y), winding type (code C)

VI. Performance parameters

I. A screw type connection Inlet diameter Spray angle (°) Quantity of flow (m3/h) at various pressures (kg/cm2) Thread size mm 60 90 120 0.5 0.7 1 2 3 2.4 · · · 0.14 0.16 0.19 0.27 0.33 G1/4" 3.2 · · · 0.25 0.3 0.36 0.5 0.62 (external diameter Ф13.2) 4 · · · 0.39 0.46 0.55 0.77 0.95 4.8 · · · 0.58 0.69 0.82 1.16 1.42 G3/8" 5.6 · · · 0.79 0.93 1.11 1.57 1.92 (external diameter Ф16.7) 6.4 · · · 1.03 1.21 1.45 2.05 2.51 7.9 · · · 1.6 1.89 2.26 3.19 3.91 G1/2" (external diameter Ф21) 9.6 · · · 2.33 2.75 3.29 4.66 5.71 11.1 · · · 3.19 3.77 4.51 6.36 7.8 12.7 · · · 4.06 4.81 5.74 8.1 9.96 G3/4" 15.9 · · · 6.48 7.68 9.18 12.96 15.9 (external diameter Ф26.4) 19.1 · · · 9.18 10.86 12.96 18.3 22.44 G1" 22.2 · · · 12.48 14.76 17.64 24.96 30.54 (external diameter Ф33.2) 25.4 · · · 16.32 19.32 23.1 32.64 40.02 G1 1/2" (external diameter Ф47.8) 28.6 · · · 18.18 21.48 25.68 36.3 44.46 34.9 · · · 27.06 32.04 38.28 54.12 66.3 38.1 · · · 34.2 40.44 48.36 68.4 83.76 G2" 44.5 · · · 49.62 58.74 70.2 99.3 121.56 (external diameter Ф59.6) 50.8 · · · 65.76 77.82 93 131.52 161.1 G3" 63.5 · · · 101.4 120 143.4 202.8 248.4 (external diameter Ф87.9) II. R hollow linear nozzle Inlet diameter Quantity of flow (m3h) at various pressures (kg/cm2) Spray orifice diameter Spray angle (°) at various pressures (kg/cm2) mm 0.2 0.3 0.5 0.7 1 1.5 2 3 mm 0.5 1.5 3 17.5 1.44 1.8 2.28 2.7 3.24 3.96 4.56 5.64 15.5 67 69 71 1.74 2.16 2.76 3.24 3.9 4.8 5.52 6.78 17.1 70 73 75 2.22 2.7 3.48 4.14 4.92 6 6.96 8.52 20.6 76 79 81 24.1 2.34 2.88 3.72 4.38 5.22 6.42 7.38 9.06 20.2 74 75 77 2.94 3.6 4.62 5.46 6.54 7.98 9.24 11.34 24.2 76 77 79 27.8 3.66 4.44 5.76 6.84 8.16 10.02 11.52 14.16 25.8 72 74 76 4.38 5.34 6.9 8.16 9.78 12 13.86 16.92 28.6 74 76 78 36.5 5.1 6.3 8.1 9.6 11.46 14.04 16.2 19.86 27 68 70 73 5.88 7.2 9.36 11.04 13.2 16.14 18.66 22.86 30.2 70 72 75 6.6 8.04 10.38 12.3 14.7 18 20.76 25.44 32.9 72 74 78 7.26 8.88 11.46 13.56 16.2 19.86 22.92 28.08 36.1 74 77 82 8.7 10.68 13.8 16.32 19.5 23.88 27.6 33.78 39.7 77 79 84 47.6 10.2 12.48 16.14 19.08 22.8 27.9 32.22 39.48 40.5 69 71 74 11.7 14.28 18.48 21.84 26.1 31.98 36.9 45.18 44.1 71 73 77 13.14 16.08 20.76 24.6 29.4 36 41.58 50.94 47.6 73 77 80 14.46 17.76 22.92 27.12 32.4 39.66 45.84 56.1 50.8 77 79 83 57.2 17.46 21.36 27.6 32.64 39 47.76 55.14 67.56 52.4 71 73 77 20.4 24.96 32.22 38.16 45.6 55.86 64.5 78.96 58.7 73 75 80 79.4 22.02 26.94 34.8 41.16 49.2 60.24 69.6 85.2 50.8 66 67 70 25.5 31.2 40.32 47.7 57 69.84 80.58 98.7 59.1 68 70 71 29.22 35.82 46.26 54.72 65.4 80.1 92.46 113.28 68.3 70 72 74 33 40.44 52.2 61.74 73.8 90.36 104.34 127.8 74.6 72 74 77 36.48 44.7 57.72 68.28 81.6 99.96 115.38 141.36 82.6 74 76 81 40.26 49.32 63.66 75.3 90 110.22 127.26 155.88 92.1 78 80 83 124 43.74 53.58 69.18 81.84 97.8 119.76 138.3 169.38 69.9 66 68 70 51.24 62.76 81.06 95.88 114.6 140.34 162.06 198.48 76.2 68 70 72 58.5 71.64 92.46 109.44 130.8 160.2 184.98 226.56 82.6 70 73 75 65.76 80.52 103.92 123 147 180.06 207.9 254.58 88.1 72 75 77 72.96 89.4 115.38 136.56 163.2 199.86 230.82 282.66 97.2 74 76 79 80.52 98.58 127.26 150.6 180 220.44 254.58 311.76 108 76 79 83 91.5 112.08 144.66 171.18 204.6 250.56 289.32 354.36 130 78 81 86 III. C1 tobacco pipe type nozzle Work condition

Technical param

- eters

Specifi

- cationWorking pressure 0.2MPa Working pressure 0.3MPa Working pressure 0.4MPa Install

- ation dimen

- sionQuan

- tity

of

flowFog

crown diam

- eterSpray angle Spray Quantity of flow Fog crown diameter Spray angle Spray Quan

- tity

of

flowFog

crown diam

- eterSpray angle Spray G" m3/h m ° m3/h m ° m3/h m ° Ф3 0.25 1.5 80 common 0.35 1.6 90 favorable 0.45 2 100 Good G1/2 Ф4 0.4 1.5 80 common 0.5 1.8 90 favorable 0.6 2.5 100 Good G1/2 Ф5 0.5 1.5 80 common 0.65 2 90 favorable 0.8 2.6 100 Good G1/2 Ф6 0.6 1.6 80 common 0.75 2 90 favorable 0.9 2.6 100 Good G1/2 Ф7 0.85 1.6 80 common 1 2 90 favorable 1.25 2.6 100 Good G1/2 Ф8 0.92 1.7 80 common 1.15 2 90 favorable 1.35 2.6 100 Good G1/2 Ф10 1.2 1.8 80 common 1.5 2.3 90 favorable 1.75 2.8 100 Good G1/2 Ф12 1.5 2 80 common 1.85 2.5 90 favorable 2.25 3 100 Good G1/2 IV. C2 tobacco pipe type nozzle Working condition

Technical param

- eters

Specifi

- cationWorking pressure 0.2MPa Working pressure 0.3MPa Working pressure 0.4MPa Install

- ation dimen

- sionQuantity of flow Fog crown diameter Spray angle Spray Quantity of flow Fog crown diameter Spray angle Spray Quantity of flow Fog crown diameter Spray angle Spray G" m3/h m ° m3/h m ° m3/h m ° Ф16 2.85 2.5 100 common 3 2.8 100 Good 3.5 3 100 Good G3/4 Ф20 5.5 2.5 100 common 7 2.8 90 Good 8.5 3 100 Good G3/4 Ф25 12 2.5 100 common 14 2.8 90 Good 17 3 100 Good G1 -

Performance curve Performance parameters Structure description Overall size and mounting size of the pump

-

- Company:

Yixing Linggu Plastic Equipment Co., Ltd. ADD:Yixing porcelain DingShu Zhen Tong Li Industrial Park Road on the 1st Zipcode:214222 Contact:Chen bosheng Tel:+86-510-87409633,87403572,87403345 Fax:+86-510-87426968 E-mail:pump-cbs@pub.wx.jsinfo.net website:http://www.ldmzyj.org/ Shopsales:http://yxlgby.1688.com

- Home| About| Product| Honor| Style| Online| Contact| 中文版

Copyright(C)2015,Yixing Linggu Plastic Equipment Co., Ltd.(Yixing Engineering Plastic Equipment Factory) All Rights Reserved. Supported by ChemNet ChinaChemNet Toocle Copyright Notice